- DQ10006

- 7-15 days

- 100000 sheets/month

- 130*330cm/sheet

- 0.5mm-28mm

- ODM/OEM

✔ Feature: Wear-resistant, Impact-resistant, Heat-resistant, Cold-resistant, etc.

✔ Hardness: 0~18 shore

✔ Can be cut-to-size to form gaskets, straps, and pads.

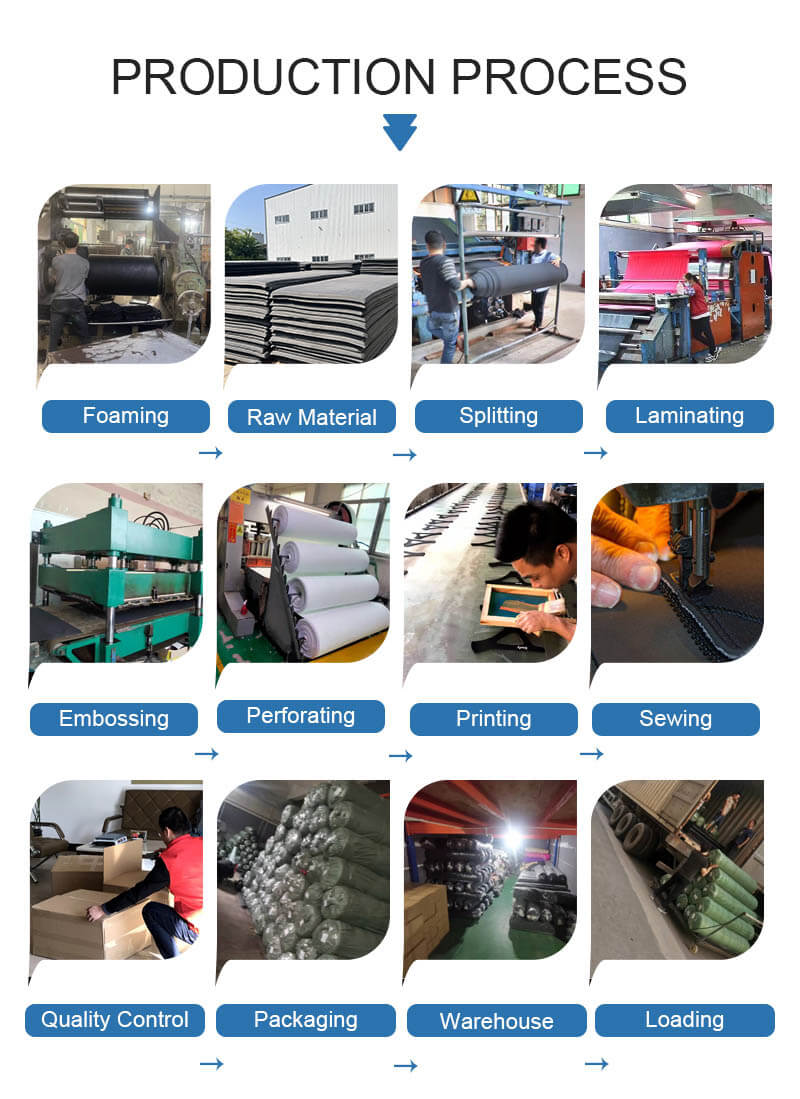

✔ Can be splitting, laminating, embossing, perforating(punching hole)

✔ Certification: RoHS, Reach

Product Description:

*CR: Chloroprene Rubber(Neoprene)

*SBR: Styrene Butadiene Rubber

*SCR: Combines SBR and CR, producing several grades that can be used in a wide range of applications, such as sports, medical , horse blanket and protection accessories. They are different in grade and composition but with similar applicaiton. Also, we developed a CS sponge this is SBR/CR compound rubber with high hardness, best for usage which require high hardness.

* The Neoprene foam is made up of cells that are closed off from one another. Using SBR SCR CR neoprene foam material, the effect of compression and shock absorption is very significant, and it is also environmentally friendly and non-toxic.

Application parameter:

| COMPOSITION | SUITABLE APPLICATION | |

| CR | SBR/OTHER | |

| 10% | 90% | shoe insole, bag, protection accessories |

| 15% | 85% | fishing wader, glove, medical care, sport protection accessories, horse blanket, shoe, bag |

| 15% | 85% | waist trimmer, shoe, bag, protection accessories, mouse pad, seater pad |

| 30% | 70% | fishing wader, glove, medical care, sport protection accessories, horse blanket, shoe, bag |

| 51% | 49% | fishing wader, glove, medical care, sport protection accessores, horse blanket, shoe, bag |

| 12% | 88% | shoe insole, bag, protection accessores, industrail materials |

Advantages:

15+ Years in Neoprene Filed, and Have Professional Service Team for Our customers.

We Have Our Own Factory, the Total Area of the Factory More Than 4000 m²

Exporting Product to More Than 180 Countries and Regions

ISO9001, CE, TUV, ROHS, SGS Approved

Parameter:

| Grade | DQ1001 | DQ2001 | DQ3001 | DQ4001 | DQ5001 | DQ6001 |

| Elongation Rate(%) | 500↑ | 450↑ | 350↑ | 300↑ | 250↑ | 150↑ |

| Tensile strength(kg/cm2) | 10↑ | 6.5↑ | 6↑ | 5.5↑ | 5↑ | 5↑ |

| Tearing strength(kg/cm) | 3↑ | 2.5↑ | 2↑ | 2↑ | 1.5↑ | 1.5↑ |

| Hardness(Type C) | 9~11 | 5~7 | 5~7 | 5~7 | 5~7 | 10~13 |

| Hardness(Shore 000) | 72~77 | 65~69 | 65~69 | 65~69 | 65~69 | 73~79 |

| Density(g/cm3) | 0.3+/-0.02 | 0.23+/-0.02 | 0.2+/-0.02 | 0.2+/-0.02 | 0.2+/-0.02 | 0.22+/-0.02 |

| Water absorption by weight(%) | 2↓ | 2↓ | 3↓ | 3↓ | 3↓ | 3↓ |

| Shrinkage(70C, 22hrs)% | 3↓ | 3↓ | 3↓ | 3↓ | 3↓ | 3↓ |

| Compression set%(22hrs, 25C) | 15↓ | 15↓ | 20↓ | 25↓ | 25↓ | 25↓ |